The Opening of our New, In-house Machine Shop – Metamex!

Share this article:

Here at Excell, we are pleased to announce the completion of our £250k expansion program with the opening of our new in-house machine shop, Metamex Engineering Ltd. Our entire expansion consisted of 8 new members of staff with two Marketing Executives, three Apprentices at Excell and three new members of staff in Metamex, as well as the opening of our Machine Shop.

What This Means To Us:

We are truly grateful for the support from our customers and team, that has led towards the opening of Metamex. For the last two years, the world has been in a struggling battle against COVID—19 and the numerous laws and regulations that have followed. Despite the highs and lows that came as a result, we are extremely proud to have been able to go ahead with this expansion and become an even more self-sufficient Excell.

The opening of Metamex will mean several things, not only for our business, but for the service that we will be able to give to our customers.

An in-house machine shop will mean faster quotes and lead times for those customers placing first time orders, or jobs that require new tooling.

As well as improving lead times, this opening also means that we are becoming far more self-sufficient and lowering our carbon footprint.

Metamex will be home to four new, specialist machines, with state-of-the-art technology.

These machines are:

- Gasparini PBS Synchronised 075 – Press Brake

- Colchester Combi 6000 – Lathe

- YCM EV1020A – Milling Machine

- HLC-H1530 – Laser Cutter

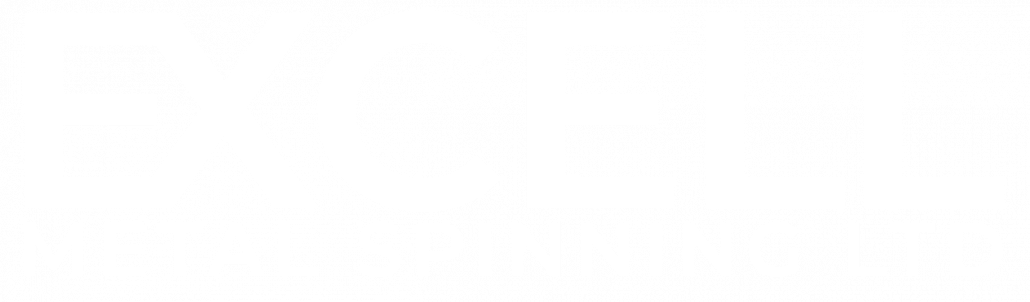

Press Brake - Gasparini PBS Synchronised 075

Our press brake is/does:

The press break is one of four new machines to arrive at Metamex Engineering Ltd.is the Gasparini PBS Synchronised 075. Press brakes are useful as they can bend thick sheets of metal to make brackets and form certain bends and shapes in parts. This is done by lowering a punch onto the sheet that will form the bend. This is repeated and reset multiple times until the desired result has been achieved.

There are several different types of press brakes that have different forms of force. These can be hydraulic, pneumatic, electric or mechanical. The force of a press brake is measured in tonnage, and typically, hydraulic presses are used to achieve very high amounts of force, while the others provide less force. Different press brakes also have different degrees of accuracy and speeds.

The Gasparini press brake that has found its new home at Metamex is a hydraulic powered press brake and has a tonnage force of 75.

The Managing Director Lee Bligh , explains that “This machine compliments the processes we already carry out, which in turn will benefit the customers who are looking for that ‘ONE STOP SHOP’.”

How could our Press Brake help you?

Some spinning’s require certain processes followed before we can send it out, such as brackets. In the past, this service would have been outsourced and the ability to do these services in-house, will hopefully eliminate some of the delays that can be incurred.

press brake Specifications and images:

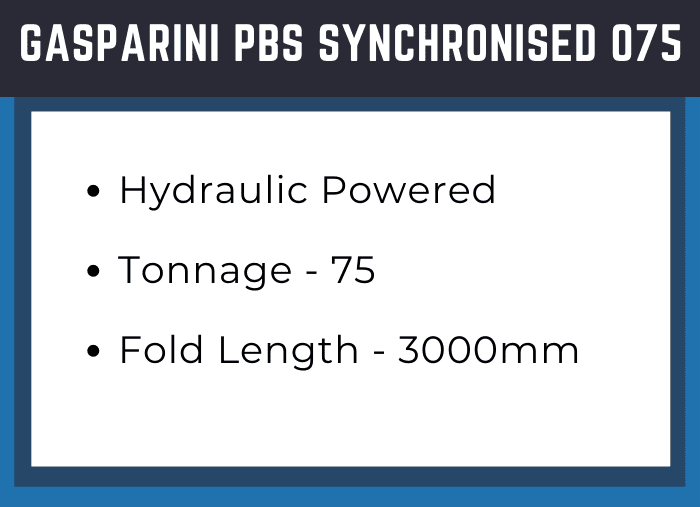

Turning Lathe - Colchester Combi 6000

Our Turning Lathe is:

The lathe in Metamex is the Colchester Combi 6000 and has a CNC feature. This will make the turning process far easier and safer in the workplace. As we are on our ever-growing ambition to hire apprentices and ensure the craft of metal spinning is kept alive, this feature will make it safer when helping them learn.

With its 6 different programming modes, it is extremely versatile for any job.

How could Our Lathe Help YOu?

Metamex will especially help Excell in provide all tooling for our spinning jobs. This lathe is large enough to take care of 95% of the tooling that we require for jobs at Excell. Not only will it improve our sustainability and self-sufficiency, but it is also opening the business to be able to serve a far wider range of businesses.

Bringing this service closer to home for not only us, but local businesses that will also be able to benefit from it, is just another reason why this expansion has been at the forefront of our mission to development and supports our mission to excellence in quality, excellence in service

Turning lathe specifications and images:

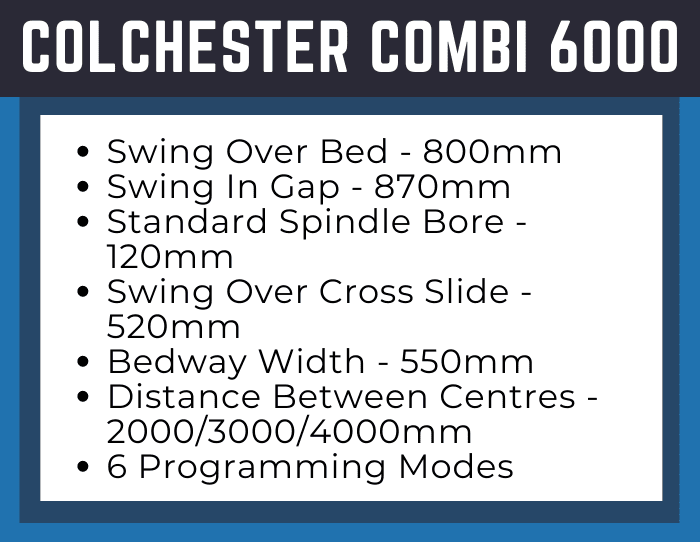

Milling Machine - YCM EV1020A

Our Milling Machine is:

The Milling Machine also making its debut at Metamex is the YCM EV1020A. As Metamex will be providing the majority of Excell’s tooling, a milling machine is a necessity. With the lathe alone, only tools for hand spinning machines can be made, but for these to be able to be used on the CNC machines, the mill will need to be used. After speaking to experts and some decision makers the YCM EV1020A was the mill that was chosen. It has the ability to meet all the needs we have for our customers and will also bring in an appeal from other local businesses, similarly to the Lathe.

how can our milling machine help you?

In some jobs, there are requirements for cut outs, for example, and this was previously outsourced. With the milling machine, this will bring many of these jobs in-house and will cut down lead times by a generous margin and will ultimately mean that our current and any future customers will be much more satisfied with the service we can offer.

Milling Machine specifications and Images:

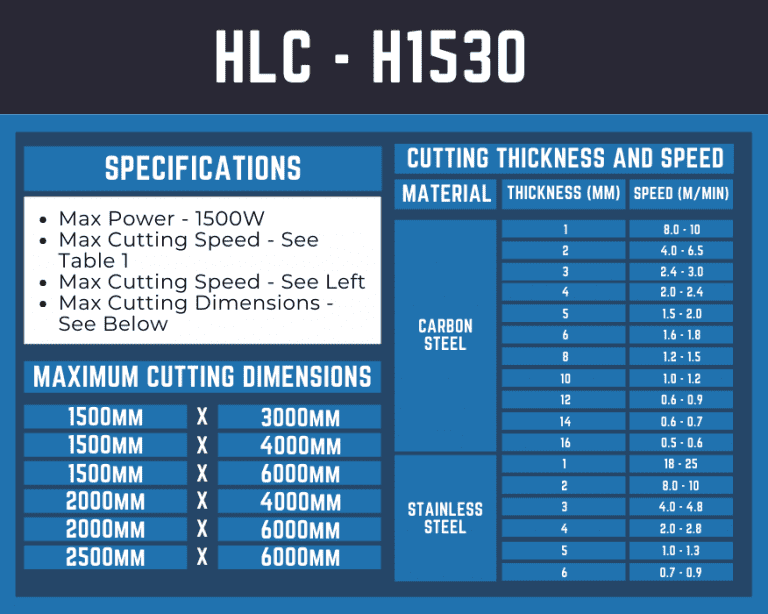

Laser Cutter - HLC-H1530

our laser cutter is:

The HLC-H1530 is the laser cutter that will be the final piece to our completion of Metamex. It covers all sheet sizes and thicknesses that we use here at Excell and so expands on our current service capabilities.

How can our laser cutter help you?

The addition of a laser cutter will see improvements made within the supply chain. Due to high demand for our services, we have seen a greater requirement for a laser cutter in the supply of sheet metal circles. This is because any spin that we produce is most commonly laser cut into circles, rather than using our already in-house circle cutter. Laser cutting as opposed to circle, provides a smoother, cleaner edge and eliminates further operations along the production process. (try to get straight to the point on informative blogs to keep the reader hooked)

Laser cutting as opposed to circle, provides a smoother, cleaner edge and eliminates further operations along the production process. (try to get straight to the point on informative blogs to keep the reader hooked). It will also mean we have greater control over the quality of ‘blanks’ provided. The reduction in delays will further improve reliability and lead times.

More details coming soon while we await its arrival.

Laser Cutter Specifications:

Summary:

The opening of the machine shop will be an amazing addition to the business and will improve our service. By being able to provide a better and faster service for our customers, as well as bringing new services to the doorsteps of many local businesses.

Chris

Table of Contents

Related Articles

Tackling Common Misconceptions of Metal Spinning

Metal Spinning is fast becoming the go to process for manufactured goods. But did you know there are many misconceptions of the craft?

How Politics is impacting UK Manufacturing

Politics within the UK plays a huge role in shaping industry. Key policies are necessary for driving innovation and more!

Boosting British Manufacturing: A £360 Million Investment

Boosting British Manufacturing: A £360 Million Investment Facebook Twitter LinkedIn WhatsApp Email It’s been declared ahead of the Budget that Chancellor Jeremy Hunt will announce