Five ways to reduce manufacturing Downtime

- Chris

- Originally Posted: July 11, 2017

- Updated

Share this article:

Five ways to reduce manufacturing downtime

Whenever machinery and people are idle, products are not being made. Unplanned disruptions in production and delivery processes are the bane to business, resulting in huge waste in time and money. However, there are five ways to minimise downtime within your manufacturing processes. Let us look.

Employees

Training is of huge importance. For instance, it can minimise user error which in most cases is the cause for manufacturing downtime. It can also ensure the prevention of too much force on a component as well as ensuring correct materials are in use. Additional training is also required for specialised tools in manufacturing.

Clear communication between manager and employee can also limit downtime. Specifically, better explanation of downtime and business profits, will see a company gain additional boost in efficiency. Even more so is the fact that employees will feel like a team, especially when they are included in decision making which can lead to increased productivity. In addition, ideas from Kaizen groups can limit downtime, increase morale, and provide higher quality goods.

Maintenance

Preventing machine malfunctions can limit manufacturing downtime and as a result, prevent a slowdown of the manufacturing process. Regular maintenance and installing new machinery is necessary to limit downtime. Similarly, keeping managers updated and they themselves suggesting updates to improve productivity also helps. Businesses should implement and practice regular ongoing preventative maintenance strategies to reduce waste.

Regular Evaluations

Within regular performance reviews, include discussions of downtime planning. Evaluations need to be honest and straightforward. Furthermore, they should look at areas of excellence and areas of improvements.

Incentives and goals

Businesses should offer incentives to employees who reach designated goals. Penalising employees for excessive downtime are the natural response from other companies. This results in the wrong message and emphasis for company efforts. Incentives motivate employees thus helping production efforts. Ideas of incentives include gift cards, paid lunch, and small get-togethers. In other businesses, smart managers would post reports which help staff members feel valued for their achievements within the company.

Track downtime and monitor efficiency of manufacturing processes

Businesses should always accurately track downtime. Moreover, there are automatic trackers available that can help alert you in real-time problems that have occurred. This, therefore, allows you to figure out why problems have occurred, thus allowing you to take necessary action to prevent the problem from arising.

Chris

Table of Contents

Related Articles

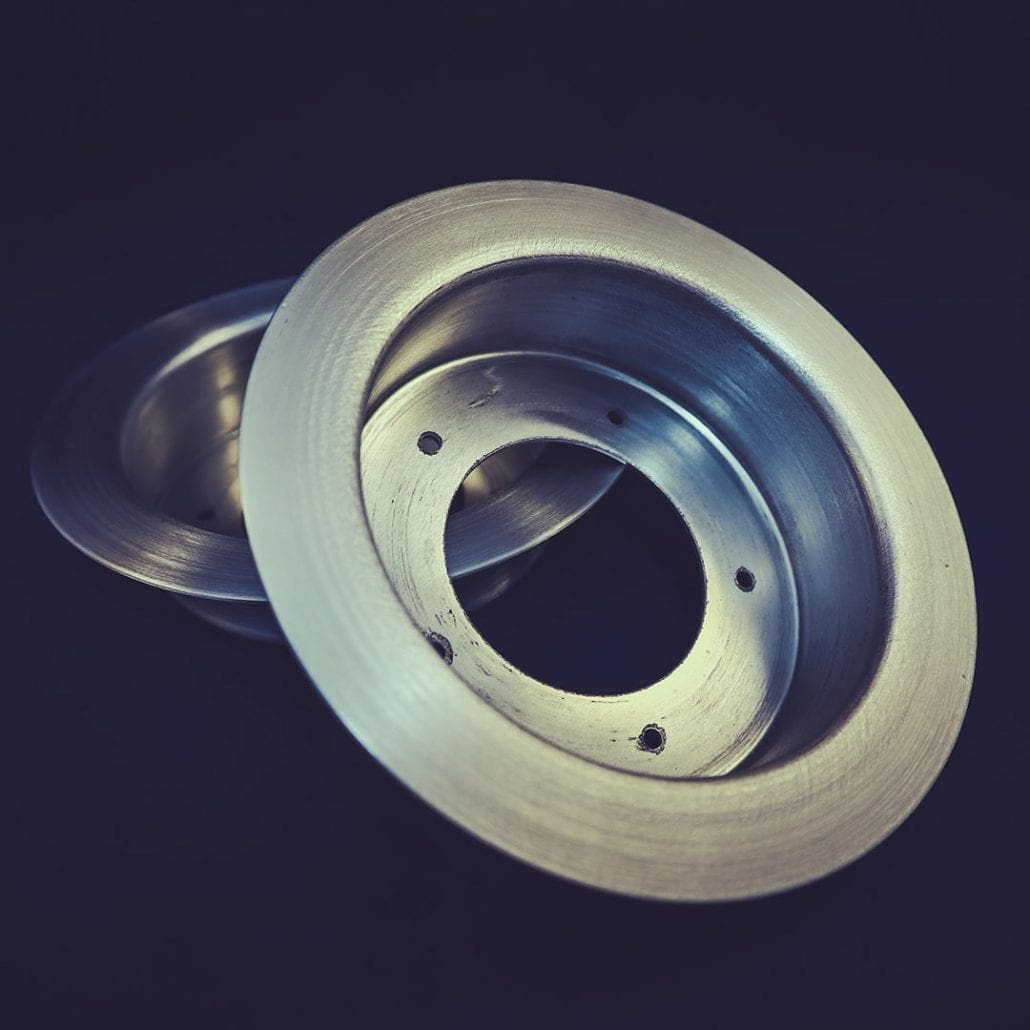

Metal Spinning Advantages and Disadvantages

This blog post aims to address these questions, the first in brief, the second in a little more detail by highlighting the advantages and then the disadvantages.

Excell Metal Spinning Invest in the Future

Share on facebook Share on twitter Share on linkedin Share on pinterest Machinery Expansion Excell Metal Spinning Ltd. expands with new Machinery upon investments worth

Excell’s Holiday Survival Guide 2019

Share on facebook Share on twitter Share on linkedin Share on pinterest Holiday Season Metal spinning tools will be downed, and turkey’s will be prepped.